APPLICATIONS

Agricultural Heating Uses

- Swine houses

- Poultry houses

ADVANTAGES

- Easy to use and cost-effective.

- Simple installation and operation.

- All thermal energy used will come into the broiler house and there are no flue losses

- Quick solution for heating livestock barns.

- No need for a heat distribution network.

- Simple to control with a thermostat or most environmental controllers.

- Exceptional reliability and durability.

- Easy maintenance.

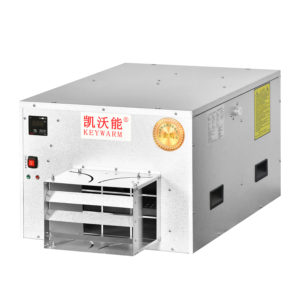

HOW IT WORKS

The thermostat calls for heating. The circulation fan starts and the ignition control system starts to ignite and burn. The combustion products are mixed with the heated circulating air to achieve the purpose of heating.

The air heater has an open combustion chamber, which means that all the heat from the combusted gas enters the room, ensuring 100% heater efficiency.

- Natural gas or LPG.

- Rates 100/170/240 x1,000 Btu/hr or 30/50/70kW.

- The 12VAC low-voltage ignition controller, specially developed for HVAC industry, all troubleshoots can be easily identified by the indicator lights.

- Safer and reliable low-voltage 24 VAC combination gas valve with 100% shut off.

- Flameout protection, fan malfunction protection, and overheating protection.

- Indoors or outdoors installation.

- Heating power of pig house(kW)=volume(m³)*0.04kW/m³

- Heating power of poultry house(kW)=volume(m³)*0.07kW/m³

- The temperature in a house with a well-designed forced-air space heating system is relatively uniform from floor to ceiling and around the house. Poultry houses and pig houses commonly are rated 30kW to 70kW. The industry standard is to provide around six to eight heaters in a 120 long broiler house, rather than four large heaters. This improves heat distribution in the house.

- Large heaters are only marginally more expensive than units with half the kW capacity, so it is common to over-design for houses that will contain brooding chicks.

- Space heaters operate at low gas supply pressures. Heated air is distributed with the heater fan and through mixing with the incoming ventilation air jet. Maintaining warm temperatures near the floor during early brooding is a common problem with space heaters.

- Broiler management guidelines recommend starting air temperatures of 32–35°C at day 1. Every day thereafter, the guidelines recommend decreasing air temperature incrementally until a final temperature of 19–21°C is reached at around day 27 and maintained for the remainder of the growout.

- Most space heaters use interior air and are unvented, which means they exhaust carbon dioxide, moisture, and incomplete combustion products directly into the building. Approximately 1.7 kg of water vapor is produced per kg of propane gas combusted. Thus, to prevent moisture accumulation caused by unvented heaters, it is recommended that minimum ventilation rate be increased by 14.5m³/h per kW heater capacity.

- Stir fans are commonly installed near the ceiling to circulate this hot air back to the litter where it is useful to chicks. In some instances where adequate temperatures cannot be maintained, both space and radiant heat systems are used.

- Thermostat location is important to maintain uniform temperature and energy savings.