APPLICATIONS

Industrial & Commercial Heating Uses

- Factories

- Warehouses

- Airports

- Railway Stations

- Supermarkets

- Offices,

- Gymnasiums

- Schools

- Exhibition halls

- Drying process such as food and painting.

Agricultural Heating Uses

- Greenhouses

- Poultry houses

ADVANTAGES

- Can disperse or direct heating.

- Integrated design for easy installation.

- Fully automatic operation, no need for personnel on duty.

- Wide power range, from 100kW to 1400kW.

- No need for complex water systems, low equipment failure rate.

- Quickly addresses heating issues in large spaces, warehouses, etc.

- Broad fuel adaptability, suitable for gas, oil, and other fuels.

HOW IT WORKS

A warm air generator is a stand-alone appliance serving to heat a given space and capable of operating on propane, natural gas or diesel.

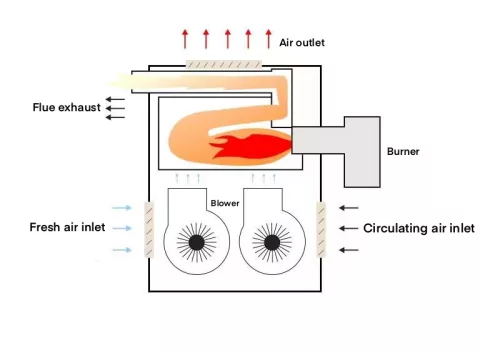

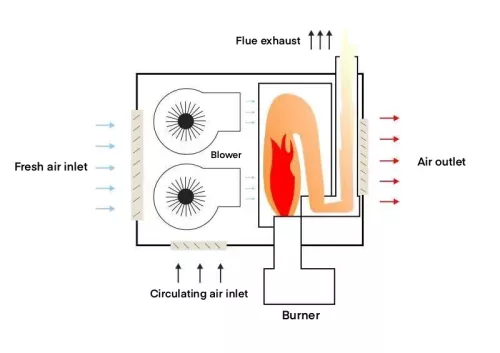

Drum-type indirect-fired air heaters mainly consist of a combustion unit, a heat exchange unit, a fan unit, a filtration unit, and a control system. They can be installed indoors or outdoors (with the option to install a mixed adjustment device for fresh air and indoor return air). Equipped with a built-in centrifugal fan, the system delivers heated air to the desired area through the air supply system, achieving the purpose of heating.

Vertical Configuaration Horizontal Configuration

- Available in vertical or horizontal configurations, suitable for indoor or outdoor installation.

- Combustion is proportionally controlled, with a thermal efficiency exceeding 90%, resulting in energy savings.

- Multiple interlocking protection measures, including flameout protection, air pressure protection, overheat protection, and low gas pressure protection.

- Large combustion chamber design, small combustion chamber volume, low NOx emissions.

- Unique heat exchange tube design, increasing smoke disturbance, and achieving high heat exchange efficiency.

Here are the criteria to consider in selecting the units:

- Vertical or horizontal units;

- Indoor or outdoor applications

- Fuel types, such as natural gas, propane, diesel and etc.

- Max. static pressure of centrifugal blower(s)

- Heating power

- Air flow rate

To start with the installation, it’s best to begin with a pre-installation checklist (a list of items to check before installation). The following is a basic checklist, intended as an example:

- Choose a suitable location for installing the heater.

- Ensure that ventilation requirements can be met.

- Examine any issues that may affect the installation of HVAC, plumbing, and electrical systems.

- Design and plan the correct fuel supply pipeline.

- Design and plan the correct supply and return air ducts (if necessary).

- Check the minimum distance from combustible materials in accordance with manufacturer recommendations and local regulations.

- Ensure equipment is easily accessible for maintenance.